Get in touch

-

Email:

sale@alumhm.com -

Tel/whatsapp:

+86-15978414719 -

Fax:

+86-0371-65621393 -

Address:

No.14 Waihuan Road, CBD, Zhengzhou, China -

Website:

https://www.aluminium-tanker-plate.com

Aluminium Tanker Plate Manufacturer

Bulk buyers sourcing aluminium tanker plate typically want the same outcome: safe, lightweight tanks with stable forming performance and predictable quality from batch to batch. Yet confusion often appears around alloy selection, temper, thickness tolerances, welding behavior, and what a manufacturer can truly guarantee.

What Aluminium Tanker Plate Means in Real Purchasing Terms

In the tanker industry, "tanker plate" generally refers to aluminium flat rolled plate used for tank shells, heads, baffles, bulkheads, and structural reinforcement parts. The manufacturers role is not only to provide thickness and width, but also to control consistency in:

Mechanical properties suitable for forming and in service vibration

Surface quality for fabrication and finishing

Flatness and residual stress to reduce distortion

Traceability documentation for audits and customer approval

For bulk procurement, the biggest risk is assuming that two plates with the same alloy designation will behave the same during rolling, bending, and welding. The same nominal alloy can vary in performance depending on melt quality, rolling practice, heat treatment control, and inspection discipline.

Common Alloys and Tempers Used for Tanker Fabrication

Most road tankers and transport tanks use aluminum magnesium alloys for a balance of strength, corrosion resistance, and weldability. Final selection depends on your cargo type, design code, and forming methods.

| Application area | Typical alloy family (examples) | Typical temper | Why buyers choose it |

|---|---|---|---|

| Tank shell and barrel sections | 5xxx series (e.g., 5052, 5083, 5454) | O, H111, H32 (varies by design) | Strong corrosion resistance, good weldability, good formability |

| Heads and dished ends | 5xxx series | O (soft) | Easier deep forming, reduced cracking risk |

| Baffles and internal parts | 5xxx series | O or H111 | Stable forming and welding, consistent flatness |

| Reinforcement and selected structural parts | 5xxx series or other engineering choices | H tempers per design | Higher strength where forming is limited |

Notes buyers often overlook:

Temper drives formability. A softer temper can reduce scrap during forming but may require design checks for strength.

For corrosive cargos, compatibility depends on the specific medium and operating conditions. When uncertain, consult your engineering team and follow recognized material selection guidance.

If your tanker design uses bulkhead components made from coil rather than plate, sourcing from the same rolling system can improve consistency across parts. For that scenario, consider specifying Aluminium coil for tankers bulkhead in the same purchasing program to reduce cross-supplier variability.

How to Evaluate an Aluminium Tanker Plate Manufacturer

A reliable manufacturer should be able to demonstrate capability across production control, inspection, and documentation, not only competitive pricing.

1) Manufacturing capability that matches tanker requirements

Ask clear questions:

Maximum width and length available for your tank design

Typical thickness range for tanker plate

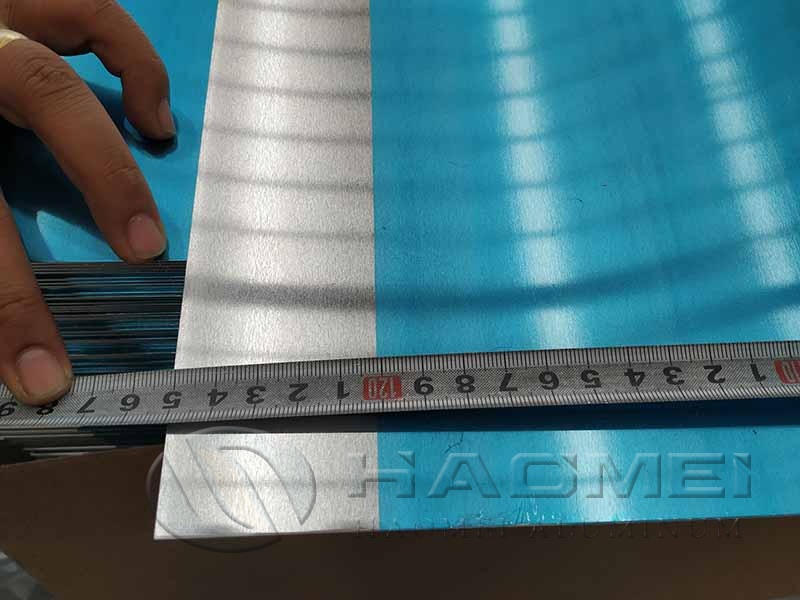

Flatness control and residual stress management

Surface finish options and protective packing

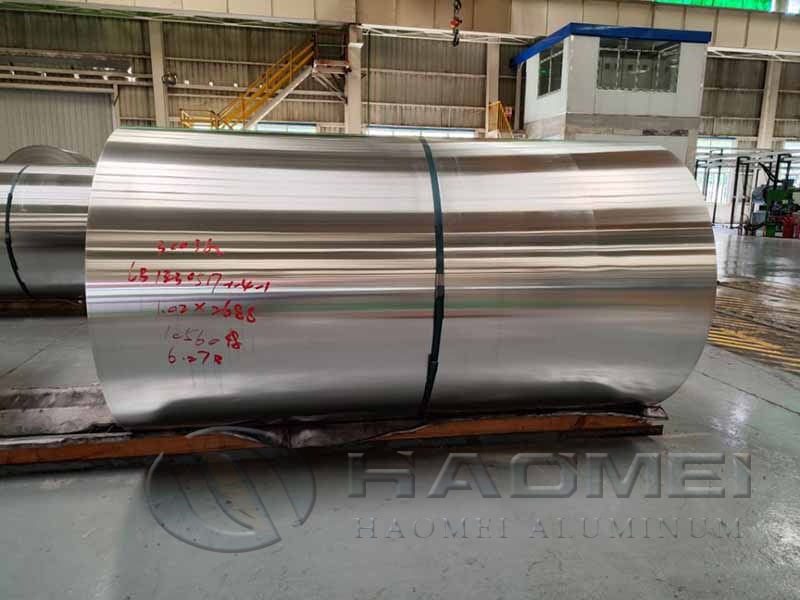

For projects requiring wider layouts to reduce weld seams, confirm whether the supplier can support wide plate supply in stable lots.

2) Quality control and traceability you can audit

Bulk buyers should request evidence of routine controls that affect forming and welding results:

Chemical composition control per batch

Mechanical testing consistency by lot

Dimensional inspection records

Identification and traceability from melt to shipment

If your procurement is for regulated transport equipment, ensure the manufacturer can provide the documentation set your customer expects, such as certificates aligned with your contractual requirements. Avoid relying on verbal promises; require written acceptance criteria.

3) Consistent supply and packaging for bulk logistics

Operationally, late deliveries and transit damage can erase any unit price advantage. Evaluate:

Lead time stability and monthly output

Pallet and crate design for edge protection

Anti moisture measures during sea freight

Marking clarity for warehouse receiving

When your fabrication uses both plate and coil formats, aligning packaging standards simplifies inbound handling and reduces identification errors. In that case, adding a defined spec line for aluminum sheets and matching labels across shipments helps your warehouse team maintain lot integrity.

Practical Specification Checklist for Bulk Buyers

To reduce confusion during quoting, provide a purchase specification that is measurable and verifiable. The following table can be copied into RFQs.

| Spec item | What to define | Why it matters |

|---|---|---|

| Alloy and temper | Exact designation and temper range | Controls strength, formability, and weld response |

| Thickness and tolerance | Nominal thickness and tolerance agreement | Predictable forming and weight control |

| Width and length | Required cutting plan and maximum deviation | Reduces scrap and rework |

| Flatness requirement | Define acceptable flatness method or limit | Prevents fit up issues and distortion |

| Surface quality | Acceptable dents, scratches, oxidation level | Impacts welding prep and appearance |

| Testing and certificates | Required inspection scope and certificate format | Supports customer audits and traceability |

| Packaging | Edge protectors, film, pallets, moisture barrier | Minimizes transit damage and claims |

When reviewing quotes, compare what is included rather than comparing price alone. A tighter tolerance or enhanced packaging can save more than it costs, especially for high volume tanker programs.

Buying Tips to Lower Total Cost Without Sacrificing Safety

Standardize a small set of alloys and tempers across tanker models where engineering allows.

Request trial lots for forming validation when switching manufacturer or rolling mill.

Align the manufacturers lot size with your fabrication batches to improve traceability.

Specify acceptance criteria for flatness and surface to prevent disputes on arrival.

Conclusion

Choosing an Aluminium Tanker Plate Manufacturer is less about finding a generic plate supplier and more about selecting a partner that can repeatedly deliver consistent properties, verified documentation, and logistics discipline at scale. By clearly defining alloy, temper, tolerances, inspection, and packaging, bulk buyers can reduce fabrication risk, improve yield, and keep tanker production schedules stable.